leeb hardness testing|leeb converted to butt section : white label The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used . 10 de jan. de 2024 · Pra descontrair. Quando a mulher fala demais.o trem complica. . . . #nossacolatina #meme #videoviral. nossacolatina · Original audio

{plog:ftitle_list}

Assaí Atacadista. 1,519,757 likes · 25,864 talking about this · 10,996 were here. 288 lojas e 49 anos de história

The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used . The Leeb hardness test is a non-destructive testing method used to determine the hardness of a material. It is particularly useful for metals and alloys, providing a quick . The Leeb hardness test is a non-destructive testing method for assessing material hardness. Know more about its properties and applications. Material selection plays a pivotal role in the volatile world of contemporary .

The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The .

The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications. The Leeb test, often conducted with a portable hardness tester, is non-destructive, making it ideal for on-site testing and for measuring the hardness of large or .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to .

The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the .The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound .The Leeb hardness test begins by placing the tester onto a flat surface and positioning the test sample inside the guide recess for it to be upright. Afterward, you place the carbide ball onto the stationary post and let it drop down vertically to reach its .Chongqing Leeb Instrument Co.,Ltd, NDT instrument manufacturer, products: hardness tester, thickness gauge, surface roughness tester, ultrasonic flaw detector. Customer Service:0086-18223160920 | E-mail:sales@leebtest .

Leeb Hardness Tester Instruction Manual . Contents 1 General description 3 1.1 Features 3 1.2 Main Application and Testing Range 3 1.3 Types and specification 5 1.4 Operating conditions - 9 2 Structure features and Testing principle 10 2.1 Structure features 10 2.2 Testing principle 12 .

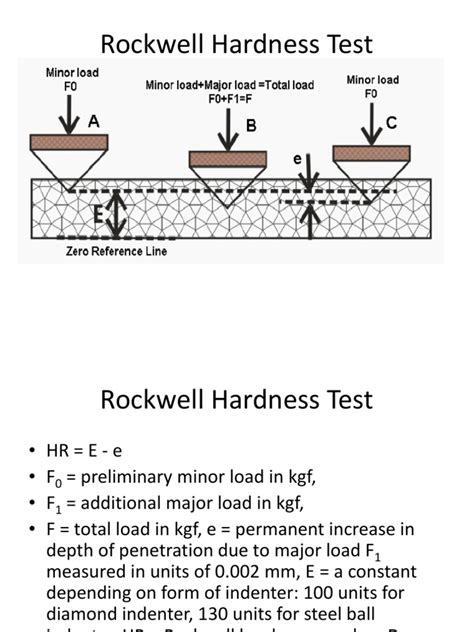

units for rockwell hardness test

The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the strength of metallic materials, that has been adapted for prediction of σ c of rock (Kompatscher 2004).The LHT device, sometimes also referred to in the literature as the Equotip, is shown in . This chapter presents different types of hardness test method, and calibration of testing machines (both direct and indirect method). Conventional static hardness methods (Brinell, Rockwell and Vickers) and dynamic Leeb rebound hardness with corresponding uncertainty calculation is discussed in this chapter.

bottled water chemical test results

The Leeb Hardness Test Instrument PCE-900 measures the hardness of nine different metals using the Leeb rebound method. This means that with the hardness test instrument a firing pin bounces on a metallic surface and the intensity of the rebound is used as an indicator of the material hardness. The Leeb Hardness Test has emerged as a powerful and versatile tool within the domain of material science testing. For those engineers seeking a cost-effective and efficient approach to evaluate the hardness and damage resistance of metallic materials, the Leeb Hardness Test presents a compelling solution. Why choose Mxmonfree Leeb hardness tester? 1. Non-destructive Testing: Leeb Rebound Hardness Test, is one of the four commonly used methods to test the hardness of the metal. It is non-destructive used to inspect workpieces weighing above 1 kg. 2.

QualiTip Plus is the latest cutting-edge Portable Rebound-type Leeb Hardness Tester, incorporating advanced micro-electronic technology and adhering to ASTM A956 standards for accuracy. Its compact design includes standard accessories such as a carrying case, test block, and probe, with an option for an extended DL ProHardness conversion tables for Rockwell, Brinell, Vickers. Hardness Testers. Durometers; Thickness Gauges EMAT; Leeb Rebound Hardness Tester | CIMETRIX Ltdconstitutes the Leeb hardness value. 6. Test Piece 6.1 Form—The Leeb hardness test is acceptable for steel, cast steel, and cast iron with varying shapes and sizes. 6.2 Thickness and Weight—The thickness and weight of the test piece shall be considered when selecting the impact device to be employed. The following guidelines are offered as

types of rockwell hardness test

Leeb Hardness Tester leeb130. Functions & Features: l English m enu, convenient and easy for operation.. l Hardness standards HL,HRB,HRC,HB,HV,HS can be used, free conversion between different standards. l Can calibrate HL,HRC,HB.. l On the basis of Leeb hardness measurement principle, can be used to detect a variety of metal materials for a ccurate and stab le .The HT-1000A and HT-2000A hardness testers operate on the Leeb principle, a dynamic hardness test method based on velocity measurement. They include a guide tube and an impact body. The impact body contains a magnet and tungsten-carbide ball, measurements are performed using a spring to propel an impact body through a guide tube towards the .

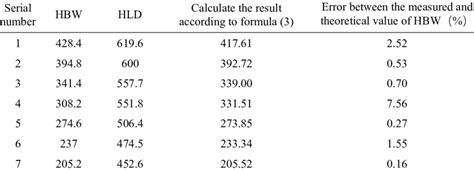

(4)If you want accurate conversion from the Leeb hardness value to other hardness value, contrastive test is needed to get conversion relations for the special material. Use inspection qualified Leeb hardness tester and corresponding hardness tester to test at the same sample respectively. For each hardness value, each measure homogeneously 5 . 5.1 Hardness of a material is a poorly defined term that may have many meanings depending on the type of test performed and the expectations of the person involved. The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested.

Leeb rebound hardness testing is mainly used for metals but also for composites, rubber and rock testing. Excellent for material selection, acceptance and production level testing, e.g. in the automotive industry; Ideal for on-site .

In this video, you will get an overview of the full-featured UNI-T UT347A Leeb Hardness Tester.The UNI-T UT347A is a highly accurate and portable Leeb Hardne. It calculates hardness by using an impact ball to bounce off the hardness surface, and the formula for Leeb Hardness HL=1000×VB (rebound speed) / VA (impact speed). The most commonly used portable Leeb hardness tester can convert Leeb (HL) measurements into Brinell (HB), Rockwell (HRC), Vickers (HV), and Shore (HS) hardness.

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Leeb hardness test adalah metode uji dinamis dan memiliki karakteristik sebagai berikut:. Ini adalah salah satu metode standar (ISO 16859, ASTM A956).Tergantung pada metodenya, kecepatan tumbukan antara 1,4-3,0 m/s. Ini adalah metode uji pantulan, yang berarti bahwa untuk menentukan nilai kekerasan benda uji, kecepatan penabrak diukur sebelum dan sesudah .

Impact device. D. DC. DL. D+15. C. G. Application. For the majority of your hardness testing requirements. Use in very confined spaces, e.g. in holes, cylinders or for internal measure‐ ments on assembled machines.

portable leeb hardness tester

The Leeb Hardness Tester PCE-900 measures the hardness of nine different metals using the Leeb rebound method. This means that with the hardness tester a firing pin bounces on a metallic surface and the intensity of the rebound is used as an indicator of the material hardness.The hardness measurements are made by using the dynamic rebound testing method according to Leeb. Leeb hardness testing was invented in 1975 in Switzerland and has become one of the most popular portable testing methods currently available. The TIME Leeb Hardness testers are supplied to the industry since 1991 and can be seen as the current .

Metallic materials — Leeb hardness test — Part 1: Test method. Edition 1 2015-09. Read sample. ISO 16859-1:2015. 57828. ISO 16859-1:2015 Metallic materials — Leeb hardness test Part 1: Test method. Published (Edition 1, 2015) This publication was last reviewed and confirmed in . The Leeb hardness tester can be used in the laboratory, as well as the on-site engineering field. The digital leeb hardness tester is indispensable for material nondestructive hardness testing. Our leeb hardness tester price is very reasonable and affordable as well.

The Leeb test uses ASTM A956—Standard Test Method for Leeb Hardness Testing of Steel Products. The Leeb test is a measure of the rebound of an object from the test sample. The hardness of metals affects the rebound energy—harder materials produce a greater rebound, while softer materials dampen the rebound energy.

bottled water companies that test for pfas

bottled water container colifrm testing

WEBResumo do jogo Universidad Católica vs. Universidad de Chile Univerdad do Chile Campeonato Chileno, placar final 3-0, de 4 de outubro, 2020 em ESPN (BR).

leeb hardness testing|leeb converted to butt section